The homogenization of some viscous products requires a specific or higher flow rate. For this type of application, a traditional agitation system, utilizing a pumping impeller at high rotation speed, can generate shear forces damaging to the product structure.

In such cases EOLE4 is the solution you are looking for…

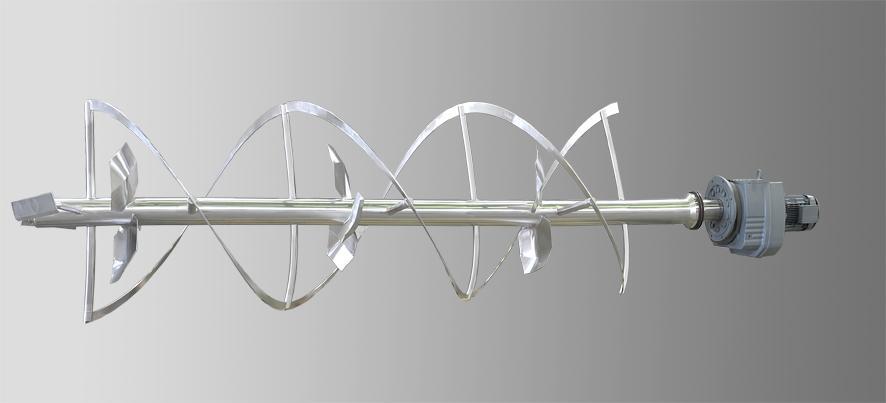

Made with several stages of the Pierre Guerin patented HTPG4 impeller and with opposing mounted helicoids, EOLE4 brings a drastic reduction of the undesired shear effects. The HTPG4 impellers ensure the axial pumping of the product from the top to the bottom in the centre of the vessel whereas the helicoids ensure the pumping in the reverse direction and along the vessel wall. The complementary action of two types of impellers reduces significantly the rotation speed compared to a traditional agitator, thus preserving the product integrity while ensuring an optimal mixing in the vessel as a whole.

Derived from the EOLE4, the EOLE5 agitator has wall scrapers in addition to the helicoids, thus allowing for heat transfer optimization and limitation of product accumulation or hot spots on the vessel wall. EOLE5 agitator is ideally adapted to cooking applications.

Applications

Cutting curd for the production of stirred yoghurts, preparation of milk dessert, convenience food, fruit jams, chocolate mixing, etc.

User benefits

- due to minimum shear effects, EOLE4 preserves product integrity

- the low speed limits the vortex and risk of air incorporation, and thus unwanted oxidation of the product

- due to the high recirculation flow rate, EOLE4 optimises the mixing time

- the hydrodynamics of the HTPG4 impellers ensures a maximum ratio: circulation flow rate /consumed power (nominal electrical demand)

- the efficiency of the mixing limits the product loss (for example during the cutting of curd).

EOLE helicoïd agitators