The smoothing of food products (fresh cheese, fruit purees, dessert creams, sauces, etc.) performed via the Lissalim machine is one of the numerous applications developed by Pierre Guérin from its alm® homogenizer range.

Alm homogenization principle:

Transferred by a rotary-lobe pump, specially designed for fragile products, the pastry product is smoothed through the alm® homogenizing head made of 10 consecutive tetrahedral cells. There, product is subjected to successive mechanical actions of cavitation, turbulence and lamination. The action of the 10 adjoining tetrahedral cells on the product is comparable to an ultrasound source of frequency of 60 000 up to 100 000 impulsions/sec. The combination of these mechanical and ultrasonic actions explains why the alm® homogenization principle requires a lower working pressure versus classical mechanical homogenizers, thus resulting in incomparable product texture and fineness.

Applications

Smoothing of viscous products: fresh cheese, yoghurts, fruit purees, dessert creams, sauces, etc.

User benefits

- patented 10 stages ultrasonic smoothing head for incomparable product texture

- versatile equipment through a large choice of obturators for various products and applications

- robust and reliable design

- low maintenance cost compared to traditional high pressure equipment

- low electrical consumption,

- acoustic level less than 80 dB

- hygienic design, cleanable in-place

- pre-mounted and pre-tested skid for easy installation and fast start-up.

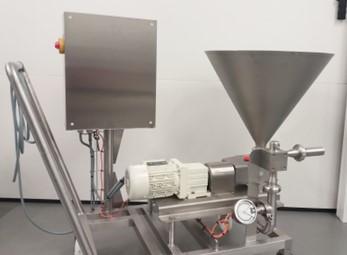

Lissalim Smoothing machine